BlueKit Lift Ventilation Systems

Saving energy with intelligent shaft ventilation

What is BlueKit and how does it work?

Ventilation is necessary for affective elevator shaft smoke extraction.

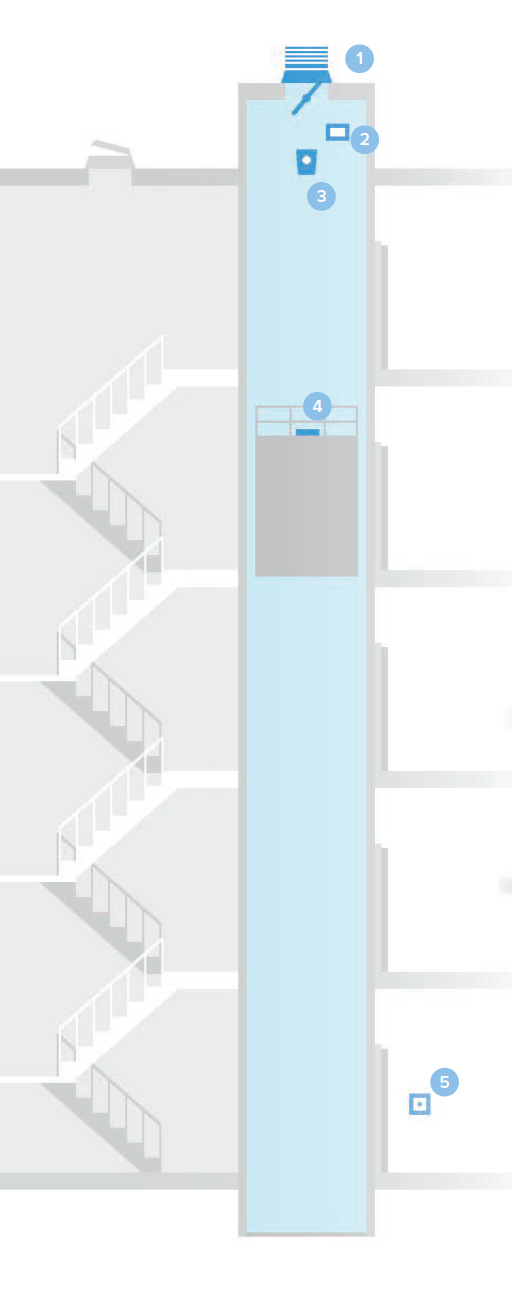

The top of the shaft has a recessed external opening through which valuable energy is also lost. Heated indoor air escapes through leaky lift doors due to the stack effect in the heating season, which leads to a huge rise in heating costs. BlueKit systems feature a closing element which is installed in the external opening of the lift shaft and prevents heated or air-conditioned indoor air from continuously escaping. In an emergency or if ventilation is required the closing element opens automatically. The BlueKit system consists of only a few components which are all certified to EN standards. It is compatible with every lift type and can easily be installed or retrofitted.

The right system for every shaft

Whether standard dimensions or special solutions: Our product variants BlueKit AIO and AIO Basic can cover all structural and technical requirements. The AIO system is used as an economical solution for standard shafts and can be combined with all smoke

detection systems. With their extended range of functions, the AIO solutions offer flexible adaptation options and are ideal for use in high-energy buildings. They are suitable for group shafts as well as lifts with machine room and can be extended with wind and rain sensors, timer and key switch. Connection to a fire alarm system (FAS) is also possible.

Your Benefits

- Reduction of energy costs

- Reliable smoke detection and demand-controlled ventilation

- Reduction of lift maintenance cycles

- Reduction of moisture and cold draughts

- Upgrading of air quality

- Sustainability due to reduction in CO2 emissions

Why BlueKit

- Tested, certified and patented technology

- Future-oriented systems

- Comprehensive service

- Collaboration with leading lift engineering specialists

The New Build Solution: Thermo Flap (TF)

THERMALLY INSULATED WEATHER PROTECTION WITH INTEGRATED VENTILATION FLAP

- Integration in thermal insulation

- 100% weather protection

- Ready-to-install solution

- Integrated louvre window – air permeability: Class 3

- Insect screen in louvre cover

- Outstanding heat transfer coefficient of 0.41 – 0.55 W/m2K

- Base made of glass fiber reinforced plastic (GFRP) prevents condensate formation

- Smoke extraction and ventilation ensured through openings on 4 sides, regardless of wind direction

- Space saving: Dimensions of louvre cover correspond to the GFRP base

Lift Standard EN 81-20

The ventilation requirements for the lift car, shaft and machine rooms of the lift cars are set out in EN 81-20 Appendix E.3. The safety and well-being of persons who are using the lift, working in the shaft or trapped in the lift car or shaft because a fault has occurred, depend

on the following factors:

- Ambient temperature of the shaft in the building

- Volatile organic substances, CO2, air quality

- Fresh air supply in the shaft

- Moisture, dust, smoke

- Airtightness of the shaft and entire building

According to the German Federal Environmental Agency for example, a value of 2000ppm for the CO2 concentration in closed rooms is unacceptable. Regular checks of the air quality around the lift car are therefore indispensable.

The BlueKit Lift-Status-Transmitter monitors influencing factors such as temperature, air quality as well as the movement and malfunctions of the lift and, if necessary, transmits a radio signal with a request for ventilation to the lift controller.

Reliable Smoke Detection

The right solution for any shaft

Infrared Detector

The SD-L-F1 smoke detection system with optical infrared beam is based on the well-known and proven Lift Beam technology. It has been improved for use in the lift shaft and consists of 2 subcomponents:

An infrared detector, which is installed in the top of shaft, and a reflector. The SD-L-F1 is EN 54-12 certified. In the standard version, the SD-L-F1 detects a range of up to 50 meters and in the addition even up to 120 meters.

Point Smoke Detector

If a fire breaks out, the point smoke detectors enable reliable and fast smoke detection in the lift shaft according to the scattered light principle. The point smoke detectors are fastened to the wall of the shaft with installation brackets. They can be used to monitor lift shafts, machine rooms and/or evacuation levels. They are particularly suitable for challenging installation situations and low shafts.

Smoke Extraction System

With the smoke extraction system (RAS) intake pipes sample air along the entire length of the shaft. These samples are continuously monitored for fi re smoke by the evaluation unit. The system can be used for connection to a fi re alarm system (FAS) and equipped with an optional emergency power supply.

BlueKit Connect

THE INTELLIGENT WEB TOOL FOR CONFIGURATION AND CALCULATION OF BLUEKIT SOLUTIONS

BlueKit CONNECT enables solutions for extraction of smoke from lift shafts to be configured and calculated digitally, quickly and easily. Using the web-based tool, customized solutions for projects can be generated based purely on project data without requiring in-depth knowledge of the product.

During this process, the program uses information such as building type, existence of a machine room, energy standard, size of the lift shaft and further criteria. On this basis, the

program suggests the optimum solution from a technical and economic standpoint and the suggested configuration can be adapted manually at any time.

Once a suitable solution has been chosen, the corresponding calculation including estimated installation time is displayed. This can be ordered directly from BlueKit, saved or exported

as a PDF. Users with their own personal login details can save and process projects, or use them as templates.

The BlueKit System

Reliable components working together